ESRS 2 SBM-1 – Strategy, business model and value chain

As one of the leading circular economy service providers, Interzero pursues the vision of a world without waste. Offering services for closing product, material and logistics loops and innovative solutions in plastics recycling, the company helps its customers to operate sustainably, avoid waste and safeguard the supply of raw materials for future generations. Interzero is actively contributing towards climate change mitigation and resource conservation with its services.

Interzero does business with companies throughout Europe, and develops individual and industry-specific solutions for customers in all sectors of the economy. By ensuring the return of key materials and the use of recycled raw materials, Interzero works with customers to maximise their ecological and economic potential. Interzero’s network extends beyond Europe into Asian markets, where we work closely with ALBA Asia. Interzero's presence in these markets allows it to participate in sustainability initiatives within Asia, and make a global contribution to waste avoidance and recycling.

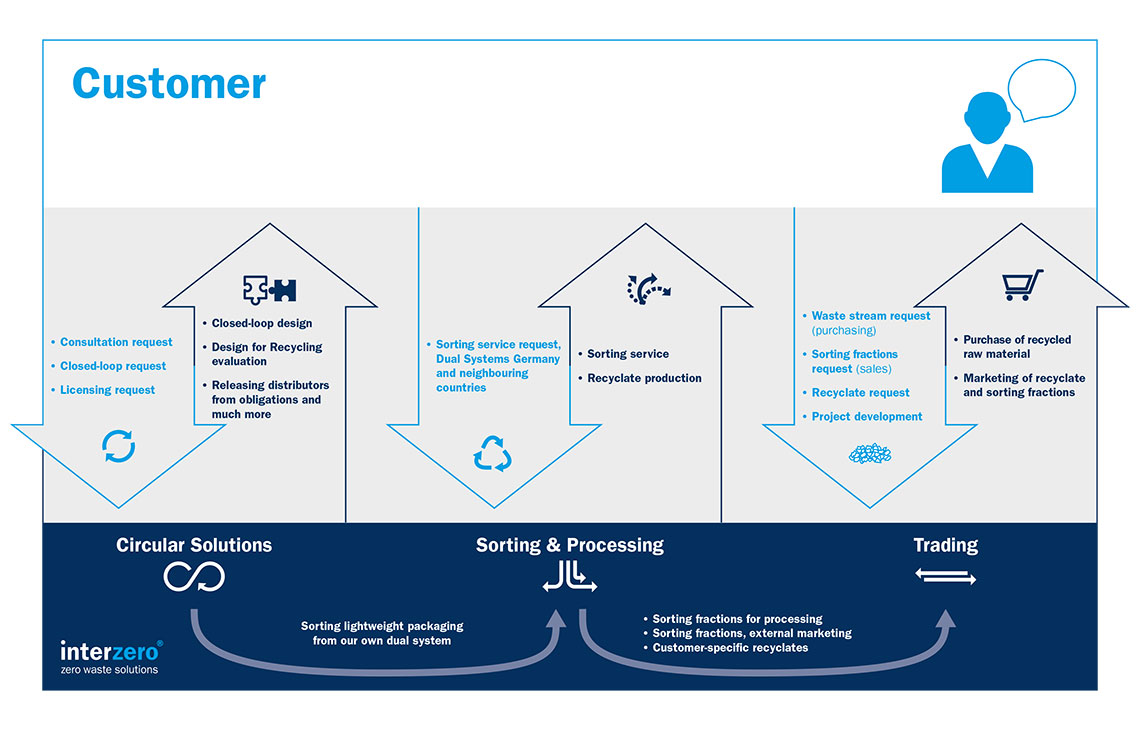

Interzero’s business model is based on two pillars: circular solutions and innovative plastics recycling. Its overarching priorities are digitisation, innovation and a comprehensive network of service, waste management and recovery and recycling partners. Along the markets, Interzero’s business is also divided into three sub-areas: Circular Solutions, Sorting & Processing, and Trading.

Circular Solutions

To prevent waste or use it for new applications, Interzero develops and operates customised recycling and reverse logistics systems based on digital supply chain and IT platforms. These optimise our customers' logistics processes whilst also reducing their costs. The company’s services to extend product life cycles comprise the organisation of global take-back systems for a wide range of packaging, products and materials, along with the development of individual one-stop solutions for companies, and advice on waste prevention and design for recycling. With the Interzero Recycling Alliance dual system, Interzero helps companies not only to meet their statutory packaging licence obligations, but also to take responsibility for closing recycling and raw material loops.

Sorting & Processing

Once the options for waste prevention and reduction, and material recovery have been exhausted, the focus then turns to recycling. Interzero has wide-ranging expertise in plastics recycling, bringing together all circular processes and technologies – from smart collection systems and high-tech sorting solutions to the creation of climate-friendly recycled materials and product applications. The company operates five facilities for sorting lightweight packaging and three facilities for plastics recycling. Interzero also operates a one-of-a-kind European cleaning plant for paper sacks, where it also produces high-quality recycled material. The company views itself as a leader in innovation, driven by its own centre of research and competence for the production of high-quality recycled plastics. Interzero works with customers to implement recyclable loops, providing access to high-quality recycled raw materials.

Trading

The Group’s Trading division handles the international marketing of many recyclates and recycled raw materials, plus other material streams from Interzero’s facilities. Interzero purchases and processes recyclables, and supplies manufacturers with high-quality recycled raw materials for new products.

Within Europe, the company operates multiple trading hubs for recycled plastics. Every year, these facilities process around 400,000 tonnes of raw materials, including plastic foils/films, hard plastics, PET bottles and EPS (expanded polystyrene). The volumes marketed here are sourced both from household waste collections (yellow bin/recyclables bin or yellow bag/recyclables bag) and manufacturers.

Interzero offers nine core services and is continuously expanding its portfolio in accordance with the objectives of its sustainability strategy. Interzero’s range of services currently includes:

- Circular solutions

- Plastics recycling

- Licensing and producer responsibility (extended producer responsibility, EPR), including via the Lizenzero online shop

- Take-back systems

- Logistics system

- Reuse

- Research and development in the field of plastic recyclates and plastic packaging

- Consulting (including via Made for Recycling service)

- Recyclables trading and products

You can find further information on Interzero’s services at https://www.interzero.de/en/services/.

The breakdown of the number of employees by geographical area can be found in ESRS S1-6.

Value chain

Interzero has developed its portfolio of products and services to enable resource-friendly product, material and logistics loops. In addition, the company seeks to assist customers and partners at every stage of the circular transition. The value chain is correspondingly complex, comprising a wide range of processes from the closed-loop economy. In this context, the packaging lifecycle can be used as a simplified illustration of how the various services along the value chain interact with one another.

Example: packaging cycle

- In Germany, the starting-point for this cycle is the collection of packaging waste from households in the yellow bin or bag. The dual system operated by Interzero offers packaging distributors a licensing process for legal compliance while also handling the collection of packaging waste. The company also informs consumers about correct waste sorting and the environmental benefits of recycling – as part of the ‘Waste separation works’ initiative, for example.

- Interzero processes the collected recyclables with state-of-the-art machinery in its five sorting facilities. The company is a European market leader in sorting services for lightweight packaging (LWP) and mixed recyclables. Every year, Interzero sorts around 800,000 tonnes of packaging waste from its own collections and collections made by other dual systems.

- The next step is to process the homogeneous plastics into high-quality regranulates for the plastics industry. In the company’s three recycling facilities, granulates are manufactured to customer specifications using an award-winning method developed by Interzero’s own research and competence centre for plastics recycling.

- Finally, Interzero advises its customers on the use of recyclates in new products, and on the design of sustainable, recyclable packaging that fully complies with the requirements set out by European legislation. The Interzero quality seal ‘Made for Recycling’ helps consumers to make environmentally conscious choices when shopping for products and encourages them to dispose of used packaging in the yellow bin – where the cycle then starts afresh.